| Place of Origin: | Baoji,China |

|---|---|

| Brand Name: | HT SENSOR |

| Certification: | CE,RoHs,ISO9001 |

| Model Number: | HT19 |

| Minimum Order Quantity: | 1 |

| Price: | Negotiable |

| Packaging Details: | Standard Export Package |

| Delivery Time: | 5-8 work days |

| Payment Terms: | Western Union, L/C, T/T |

| Supply Ability: | 5000PCS/Month |

| Material: | 316L | Accuracy: | ±0.25% |

|---|---|---|---|

| Housing Material: | Stainless Steel | Measurement Range: | 0~10kpa...20kpa....100MPa |

| Output Signal: | Mv | Power Supply: | 1.5mADC |

| Pressure Type: | Gauge/Absolute/Sealed | Product Name: | Pressure Transmitter Sensor |

| Compensated Temp. Range: | -40 To 80°C | Oil Filled: | Silicon Oil |

| High Light: | 19mm Oil Filled Pressure Transmitter,Oil Filled Pressure Transmitter Diffused,Sillcon Pressure Transmitter Water Oil Test |

||

Oil Filled Diffused Sillcon Pressure Transmitter Sensor For Water And Oil Test

19mm Silicon Piezoresistive Pressure Sensor

Introduction of Pressure Transmitter Sensor:

| Performance Parameters: | |||||

| Range | Gauge(G) | 10KPa,20KPa,35KPa,100KPa,200KPa,350KPa,1000KPa,2000Kpa | |||

| Absolute(A) | 100KPaA,200KPaA,350KPaA,700KPaA,1000KPaA,2000KPaA | ||||

| Sealed(S) | 3500KPaS,7MPaS,10MPaS,20MPaS.40MPaS.60MPaS.100MPaS | ||||

| Typ | Max | Unit | |||

| Nonlinearity | ±0.15 | ±0.3 | %F.S | ||

| Repeatability | 0.05 | 0.1 | %F.S | ||

| Hysteresis | 0.05 | 0.1 | %F.S | ||

| Zero Output | 0±1 | 0±2 | mV | ||

| Span Output | ≤20KPa | 50±10 | 50±30 | mV | |

| ≥35kPa | 100±10 | 100±30 | mV | ||

| Temperature Error-Zero | ≤20KPa | ±1 | ±2 | %F.S | |

| ≥35kPa | ±0.5 | ±1 | %F.S | ||

| Temperature Error-Span | ≤20KPa | ±1 | ±2 | %F.S | |

| ≥35kPa | ±0.5 | ±1 | %F.S | ||

| Compensated Temp. | ≤20KPa | 0~50 | ºC | ||

| ≥35kPa | 0~70 | ºC | |||

| Operating Temperature | -20~80 | ºC | |||

| Storage Temperature | -40~125 | ºC | |||

| Allowable Overload | Take the smaller value between 3 times the full scale or 120MPa | ||||

| Burst Pressure | 5X the full scale | ||||

| Long-term Stability | 0.2 % | F.S/Year | |||

| Diaphragm Material | 316L | ||||

| Insulation Resistance | ≥200MΩ 100VDC | ||||

| Vibration | No change under conditions of 10gRMS, 20Hz to 2000Hz | ||||

| Shock | 100g,11ms | ||||

| Response Time | ≤1ms | ||||

| O-ring Seal | Nitrile ring or Fluoro ring | ||||

| Filling Medium | Silicon Oil | ||||

| Weight | ~ 28g | ||||

| The parameters are tested under the following conditions: 1.5mA @ 25°C | |||||

| Outline Construction | |

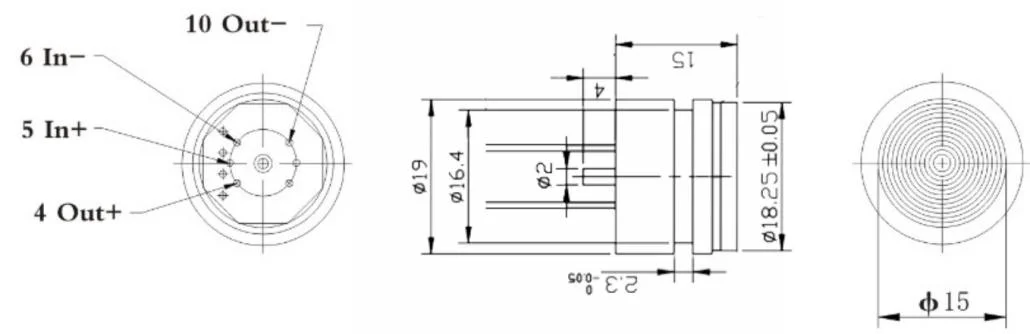

| <3.5MPaS |  |

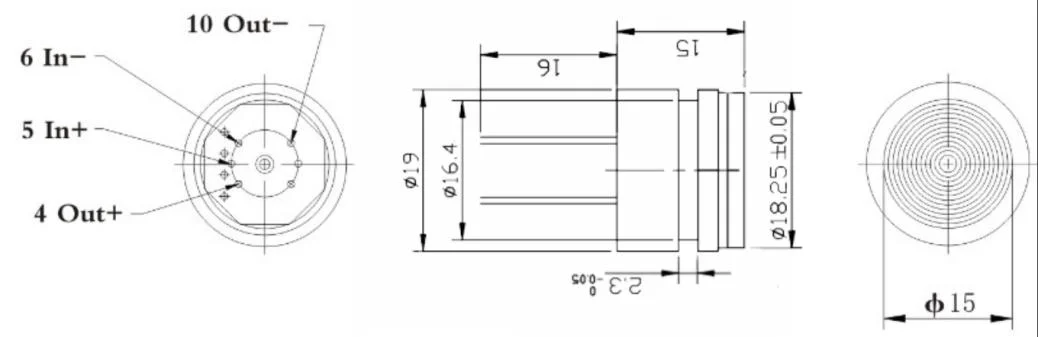

| ≥3.5MPaS <40MPaS |

|

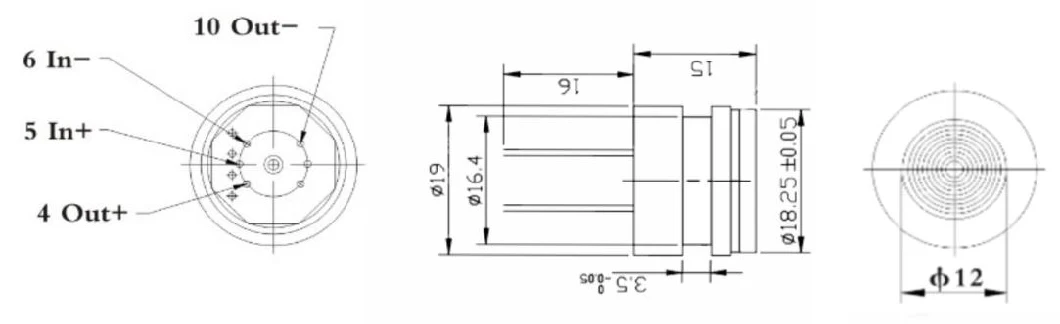

| ≥40MPaS |  |

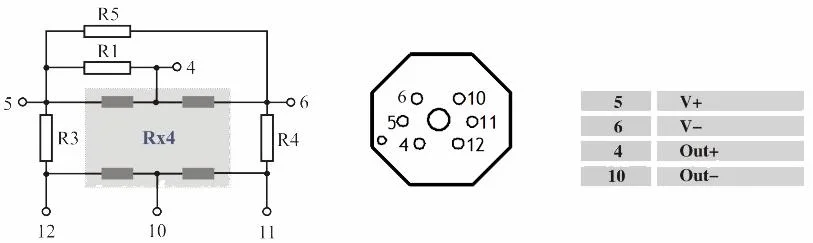

| Electrical connection and compensation |

|

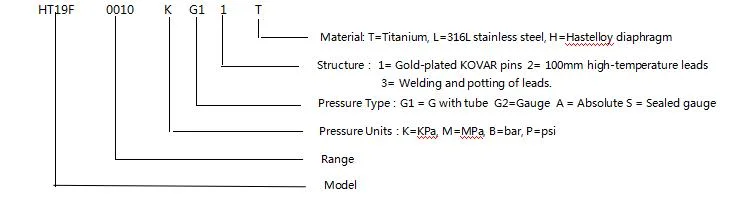

| Selection Examples |

| Ordering tips |