BP93420-IIIQT Pressure Transmitter

Introduction of Smart Pressure sensor:

The BP93420-IIIQT pressure transmitter utilizes an HT series silicon pressure-resistance isolation oil-filled core as its signal measuring element. It features a full metal flush diaphragm and direct welding with the process connection, ensuring precise connections between the process connection and the measuring diaphragm. The product has undergone thorough testing to ensure stable and reliable performance, effectively preventing problems such as pressure hole blockage caused by crystallizing media.

Product Features of Smart Pressure sensor:

1. Wide measurement range,Various pressure interface options

2. Diverse output signal options

3. Adjustable zero and full-scale

4. High accuracy,multiple sterile process connections

Applications of Smart Pressure sensor:

1.Non-corrosive gases and liquids, utilizing 316L.

2.Medical, biopharmaceuticals, and food hygiene.

3.Paper and chemical industries.

| Performance Parameters |

| Measurement Range |

-100kPa…0kPa ~ 35kPa…3.5MPa |

| Pressure Type |

Gauge Pressure, Absolute Pressure, Sealed Pressure |

| Overload |

≤ 1.5 times of the rated range |

| Accuracy @ 25ºC |

±0.25% (Typical) ±0.5% (Maximum) |

| Repeatability |

≤0.1%FS |

| Hysteresis |

≤0.1%FS |

| Long-Term Stability |

±0.1%F.S/Year(Typical) ±0.2%F.S/Year(Maximum) |

| Zero Point Temperature Drift |

±0.02%F.S/ºC(≤100KPa) ±0.01%F.S/ºC(>100KPa) |

| Full Scale Temperature Drift |

±0.02%F.S/ºC(≤100KPa) ±0.01%F.S/ºC(>100KPa) |

| Frequency Response |

2.4Khz |

| Compensation Temperature |

0-70ºC(≤10mpa,customizable) |

| Operating Temperature |

-20ºC~80ºC |

| Storage Temperature |

-40ºC~120ºC |

| Vibration |

10g,55Hz ~ 2kHz |

| Housing Material |

304,316L |

| Diaphragm Material |

316L |

| Insulation Resistance |

100MΩ 100VDC |

| Explosion-proof Rating |

Ex db IIC T6 Gb |

| Protection Rating |

IP65 |

| O-Ring Seal |

Fluoro rubber |

| Weight |

~0.3kg |

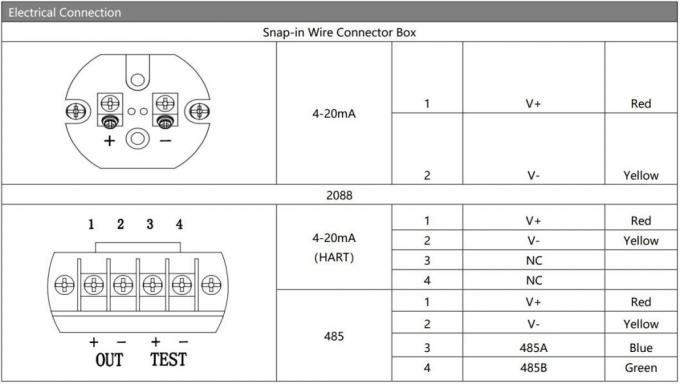

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

12~30VDC |

2/3/4 wire |

| 0~10/20mA |

3 wire |

| 0/1~5V |

| 0/1~10V |

| 0.5~4.5V |

5VDC |

| RS485 Communication Protocol |

3.6~30V / Battery |

4 wire |

1. When selecting the product, please ensure that the medium to be measured is compatible with the contact parts of the product.

2. When placing an order, please note that explosion-proof type products do not include digital display heads.

3. When ordering transmitters with an LCD or LED display head, the power supply for the transmitter should not be lower than 20VDC.

4. To ensure reliable operation of the product, it is recommended that users install lightning protection devices on-site and ensure that the product and power supply are reliably grounded.

5. The rated working temperature range of the Fluoro rubber O-ring is -20ºC to 250ºC. When the product's operating temperature is below -20ºC, it is necessary to choose an EPDM O-ring seal.

6. The default cable length is 1.5m, available in three materials. If not specified, it will be supplied with polyethylene cable material. If you require a different cable material, please specify it in the order.

7. For special requirements such as strong vibration, instantaneous impact force, strong electromagnetic or radio frequency interference, please inform our company and specify them in the order.

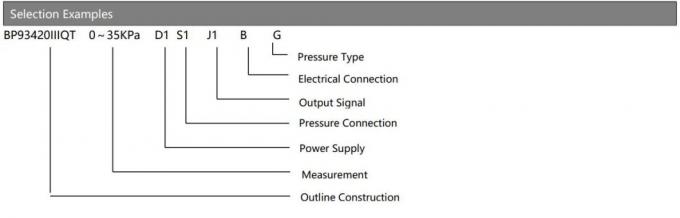

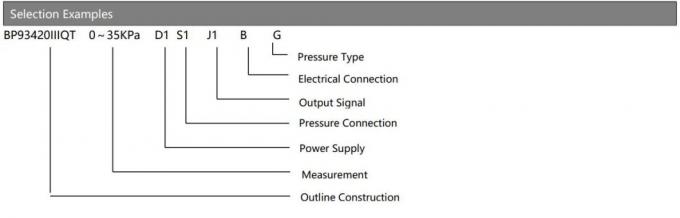

| Order Guide |

| BP93420XX |

Pressure Transmitter |

| |

Code |

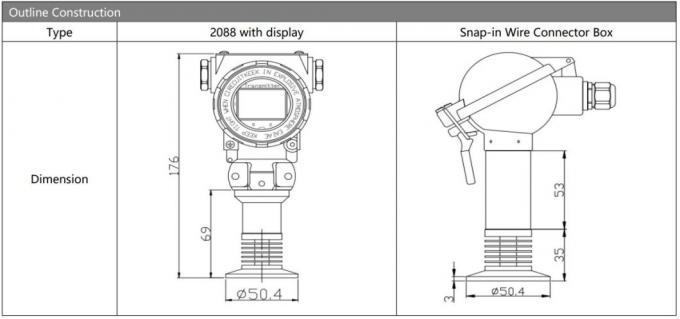

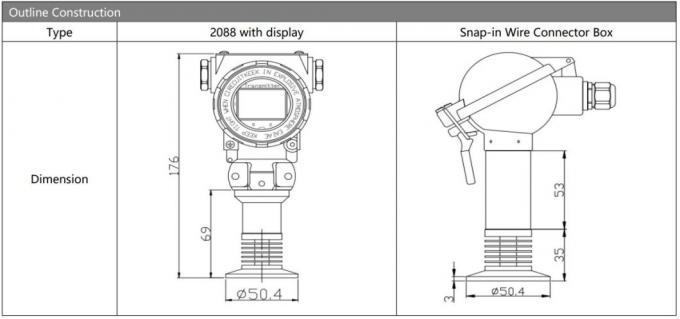

Outline Construction |

| IB |

General Pressure Transmitter |

IX |

Display Pressure Transmitter |

| IE |

Shock-resistant Aviation Pressure Transmitter |

IIC/III |

Industrial General/ Display Pressure Transmitter |

| IF |

Moisture-proof Pressure Transmitter |

IIE/IIIE |

General/Display Pressure Transmitter |

| IN |

Air Conditioning Dedicated Pressure Transmitter |

|

|

| IC |

High-temperature Pressure Transmitter |

|

|

| IQ/IQT |

Large Diaphragm /High-temperature Pressure Transmitter |

|

|

| |

Measurement Range |

-100kPa…0kPa ~ 35kPa…3.5MPa |

| (0-X)Kpa or MPa |

X: Indicates the Actual Measuring Range |

| |

Code |

Power Supply |

| D1 |

24VDC |

| D2 |

5VDC |

| D3 |

Other |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S5 |

0~20mADC |

| S2 |

1~5VDC |

S6 |

0~10VDC |

| S3 |

0~5VDC |

S7 |

0.5~4.5VDC |

| S4 |

0~10mADC |

|

|

| |

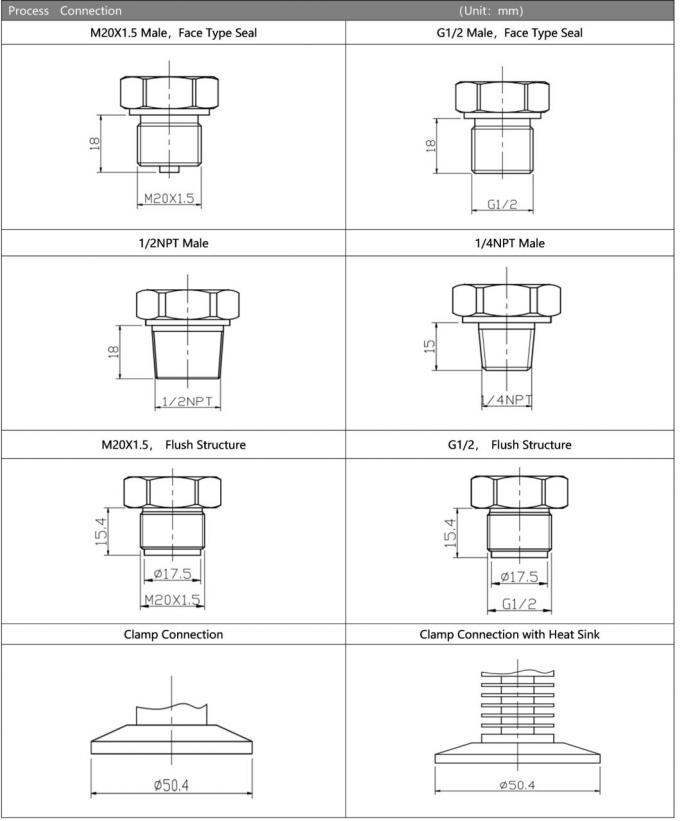

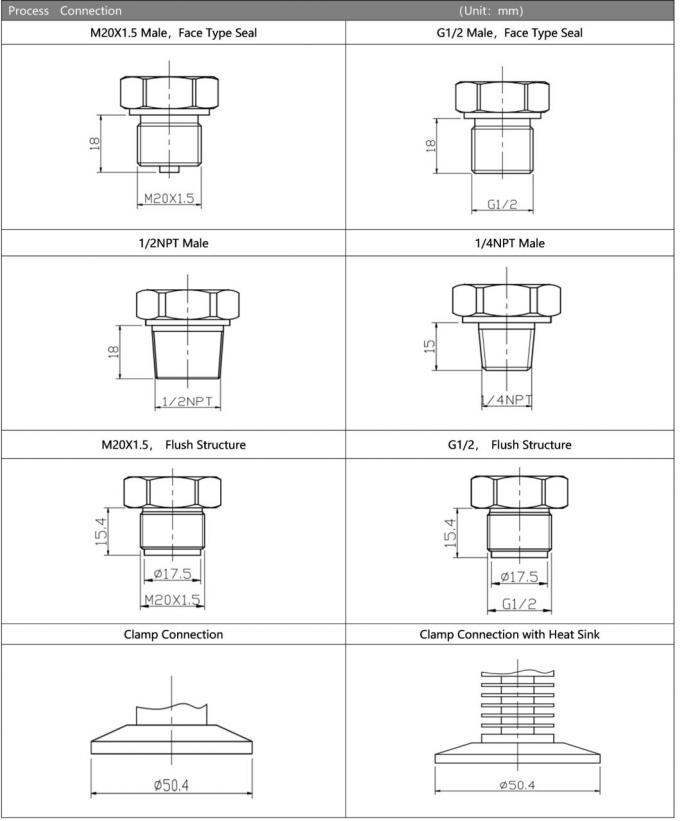

Code |

Pressure Connection |

| J1 |

M20×1.5 |

| J2 |

G1/2 |

| J3 |

G1/4 |

| J4 |

7/16-20UNF |

| J5 |

Other |

| |

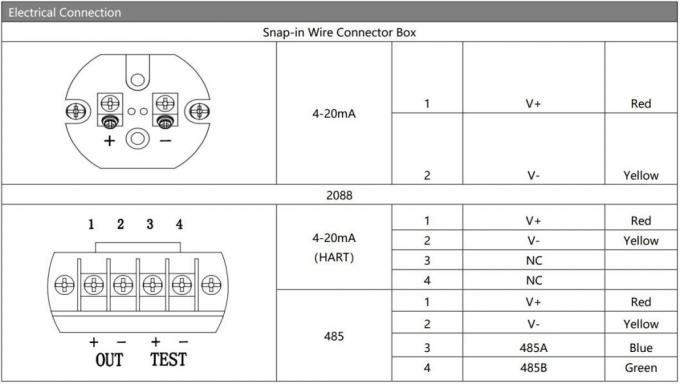

Code |

Electrical Connection |

| B1 |

Hirschmann |

| B2 |

PG7 Plug |

| B3 |

Sealed Cable Output |

| B4 |

2088 Industrial Casing |

| B5 |

2088 Industrial Casing with Display |

| B6 |

Other |

| |

Code |

Pressure Type |

| G |

Gauge Pressure |

| A |

Absolute Pressure |

| S |

Sealed Reference Pressure |

FAQ:

Q: What features do your pressure sensor transmitters offer?

A: Our pressure sensor transmitters are known for their high precision, durability, and exceptional performance. We also offer customization options to meet specific needs.

Q: Can I request special specifications for the transmitters?

A: Yes, our team of engineers can customize our products to fit your unique needs. We provide both OEM and ODM services.

Q: What is your production capacity?

A: Our manufacturing facilities have the capacity to produce up to 30,000 pressure sensor transmitters per month, making us fully capable of handling large-scale orders. However, we recommend contacting our sales team in advance to ensure smooth production and delivery scheduling.

Q: How long does it typically take for delivery?

A: For standard models, the delivery period is usually 5-8 working days. However, custom-made products may have varying delivery times.

Q: How are your products priced? Do you offer discounts?

A: Our products are competitively priced, and we do offer discounts for bulk orders or long-term partnerships.

Q: What is the warranty for your products? And what about after-sales service?

A: Our products come with a warranty of 24 months after shipment. Our after-sales service team is available to respond to inquiries within 24 hours, and we also offer remote instruction via PC network when needed.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!