Applications of silicon pressure sensor:

1. Suitable for measuring the corrosive gas and liquid pressure, compatible with 316 l stainless steel

2. Used in process control systems to monitor and control pressure.

3. Often used in refrigeration system and air compressor pressure measurement.

Electrical performance of silicon pressure sensor:

1.Power Supply: ≤10VDC

2.Common Mode Voltage Output: 50% of the input (typical)

3.Input Impedance:4KΩ~20KΩ

4.Output Impedance:2.5KΩ~6KΩ

5.Electrical Connection:100mm high-temperature wire,ribbon cable

| Performance Parameters of silicon pressure sensor:. |

| Measurement Range |

Gauge(G) |

10KPa,20KPa,35KPa,100KPa,200KPa,350KPa,1000KPa,2000Kpa |

| Absolute(A) |

100KPaA,200KPaA,350KPaA,700KPaA,1000KPaA,2000KPaA |

| Sealed(S) |

3500KPaS,7MPaS,10MPaS,20MPaS,40MPaS,60MPaS,100MPaS |

| |

Typ |

Max |

Unit |

| NonLinearity |

±0.15 |

±0.3 |

%F.S |

| Repeatability |

0.05 |

0.1 |

%F.S |

| Hysteresis |

0.05 |

0.1 |

%F.S |

| Zero Offset Output |

0±1 |

0±2 |

mV |

| Full Scale Output |

≤20KPa |

50±1 |

50±2 |

mV |

|

| ≥35kPa |

100±1 |

100±2 |

mV |

|

| Zero Offset Temp. Drift |

≤20KPa |

±1 |

±2.5 |

%F.S |

|

| ≥35kPa |

±0.8 |

±1.5 |

%F.S |

|

| Full Scale Temp. Drift |

≤20KPa |

±1 |

±2 |

%F.S |

|

| ≥35kPa |

±0.8 |

±1.5 |

%F.S |

|

| Compensated Temp. |

≤20KPa |

0~50 |

ºC |

|

| ≥35kPa |

0~70 |

ºC |

|

| Operating Temperature |

-20~80 |

ºC |

|

| Storage Temperature |

-40~125 |

ºC |

|

| Allowable Overload |

Take the smaller value between 3 times the full scale or 120MPa |

|

|

| Burst Pressure |

5X the full scale |

|

|

| Long-term Stability |

0.2 % |

F.S/Year |

|

| Diaphragm Material |

316L |

|

|

| Insulation Resistance |

≥200MΩ 100VDC |

|

|

| Vibration |

No change under conditions of 10gRMS, 20Hz to 2000Hz |

|

|

| Shock |

100g,11ms |

|

|

| Response Time |

≤1ms |

|

|

| O-ring Seal |

Nitrile rubber or Fluoro rubber |

|

|

| Filling Medium |

Silicon Oil |

|

|

| Weight |

~28g |

|

|

| The parameters are tested under the following conditions: 10V @ 25ºC |

|

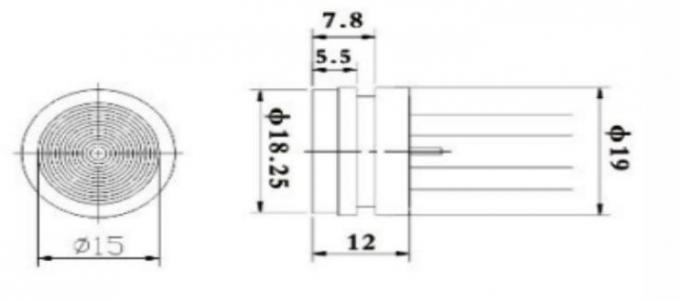

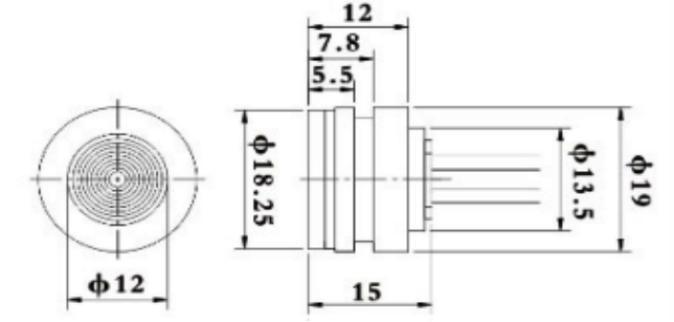

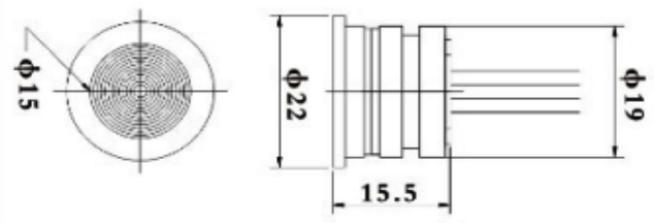

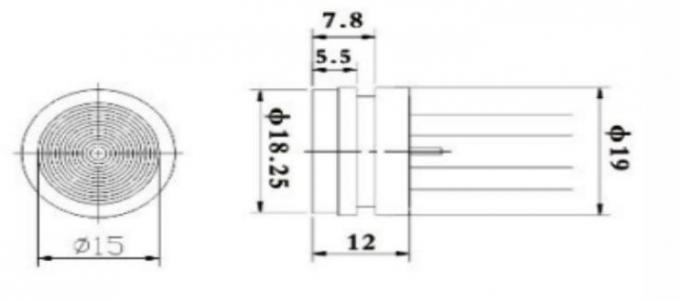

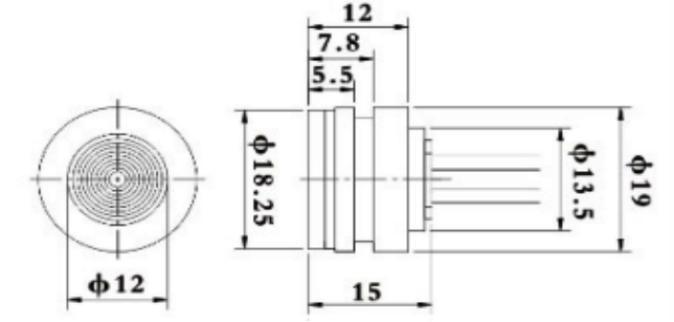

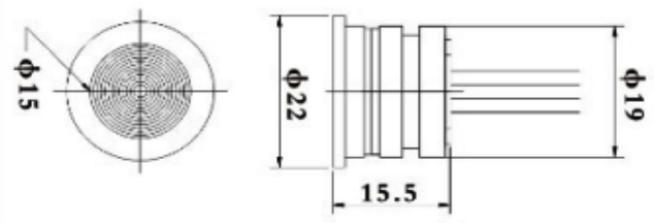

| Outline Construction of silicon pressure sensor |

| <3.5MPaS |

|

≥3.5MPaS

<40MPaS |

|

| ≥40MPaS |

|

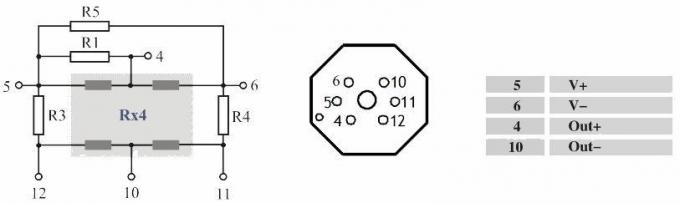

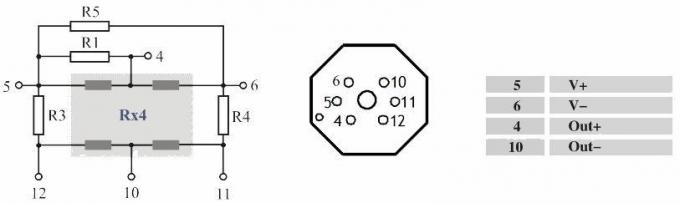

| Electrical connection and compensation of silicon pressure sensor |

|

|

1. During assembly, attention should be paid to the coordination between the core size and the transmitter housing to achieve the required tightness.

2. When assembling the housing, ensure that it is vertically aligned and apply pressure evenly to avoid damaging the compensation plate.

3. If the measured medium is not compatible with the core diaphragm and housing material (316L), special instructions should be provided when placing the order.

4. Avoid pressing the sensor diaphragm with your hands or sharp objects to avoid deformation or puncture of the diaphragm and damage to the core.

5. Keep the pressure port of the gauge pressure core open to the atmosphere to prevent water, water vapor or corrosive media into the negative pressure chamber of the gauge pressure core.

1. What factors should I consider when selecting a pressure sensor?

Pressure Range: The maximum and minimum pressures the sensor can measure.

Accuracy: The degree of measurement precision required.

Output Signal: The type of electrical signal output (e.g., 4-20mA, 0-5VDC, digital outputs).

Operating Environment: Conditions such as temperature, humidity, and exposure to corrosive substances.

Material Compatibility: Ensuring the sensor materials are compatible with the media being measured.

Response Time: How quickly the sensor responds to changes in pressure.

2. How do I install a pressure sensor?

Mounting: Securely mount the sensor using the appropriate fittings and ensure it is properly aligned with the pressure source.

Wiring: Connect the electrical output to the control system or monitoring equipment as per the manufacturer's instructions.

Calibration: Perform calibration to ensure accurate readings. This may involve setting zero and span adjustments.

Safety: Follow all safety guidelines to prevent damage to the sensor or injury.

3. How do I maintain a pressure sensor?

Regular Calibration: Periodically calibrate the sensor to maintain accuracy.

Inspection: Regularly inspect for physical damage or wear.

Cleaning: Clean the sensor and its connections to prevent contamination.

Protection: Ensure the sensor is protected from environmental factors that could affect its performance.

4. What are the common applications of pressure sensors?

Industrial Automation: Monitoring and controlling process pressures in manufacturing.

Automotive: Measuring oil, fuel, and air pressures in engines.

Medical Devices: Monitoring blood pressure and other physiological pressures.

HVAC Systems: Ensuring proper air and gas pressures.

Aerospace: Measuring cabin pressure and other critical parameters.

Environmental Monitoring: Measuring atmospheric and water pressures.

5. What is digital compensation in pressure sensors?

Digital compensation involves using microprocessors to correct errors and non-linearities in the pressure measurement. This technique improves accuracy by adjusting the sensor's output based on pre-calibrated correction factors and temperature variations.

6. What should I do if my pressure sensor is not working properly?

Check Connections: Ensure all electrical and mechanical connections are secure.

Review Calibration: Verify that the sensor is properly calibrated.

Inspect for Damage: Look for any physical damage to the sensor or its components.

Consult Documentation: Refer to the user manual for troubleshooting steps.

Contact Support: If issues persist, contact the manufacturer or supplier for technical support.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!