|

Performance Parameters:

|

| Measurement Range |

0~10m…400m |

| Overload |

≤ 2 X of rated range |

| Accuracy @ 25ºC |

±0.25% (Typ.) ±0.5% (Max.) |

| Repeatability |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Hysteresis |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Long-Term Stability |

±0.2%F.S/year (Max.) |

| Zero Point Temperature Drift |

±1.5%F.S(Typ.) ±2%F.S (Max.) |

| Full Scale Temperature Drift |

±1.5%F.Sr(Typ.) ±2%F.S (Max.) |

| Compensation Temperature |

0-50ºC (0-1m. 0-2m ); 0-70ºC |

| Operating Temperature |

-20~80ºC |

| Storage Temperature |

-30~100ºC |

| Vibration |

10g,55Hz ~ 2kHz |

| Housing Material |

1Cr18Ni9Ti |

| Diaphragm Material |

316L Stainless Steel |

| Insulation Resistance |

>=100MΩ@100VDC |

| Explosion-proof Rating |

ExiaIICT6 |

| Protection Rating |

IP67, IP68 |

| O-Ring Seal |

Fluoro rubber |

| Weight |

~0.3Kg (without cable) |

| Cable Material |

Polyethylene, Polyurethane |

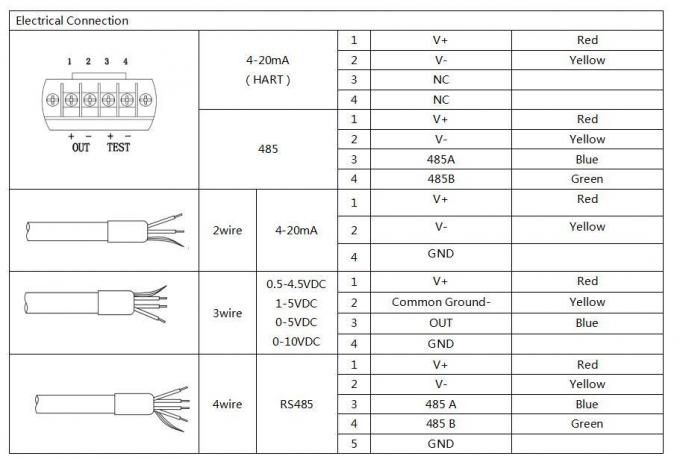

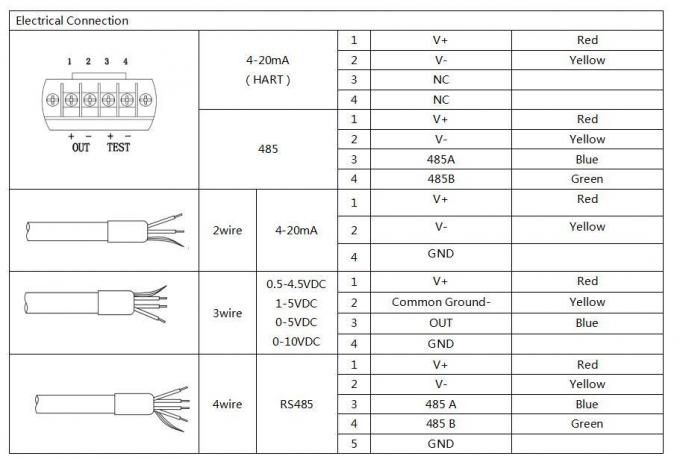

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

12~30VDC |

2/3/4 wire |

| 0~10/20mA |

3 wire |

| 0/1~5V |

| 0/1~10V |

| 0.5~4.5V |

5VDC |

| RS485 Communication Protocol |

3.6~30V / Battery |

4 wire |

Ordering tips:

Submersible Liquid Level Transmitter Ordering Guide

When ordering a submersible liquid level transmitter, it's important to consider several factors to ensure that the selected product meets your specific application requirements. Here is a comprehensive guide to help you through the ordering process:

1. Define Measurement Range

Determine the Measurement Range: Identify the maximum and minimum levels of liquid that need to be measured. Ensure the transmitter you select can accurately measure within this range.

2. Specify Accuracy Requirements

Accuracy Levels: Determine the required accuracy for your application. Different transmitters offer varying levels of precision, typically specified as a percentage of full scale.

3. Material Compatibility

Housing and Cable Material: Ensure the materials used in the transmitter (e.g., stainless steel, PVC, PTFE) are compatible with the liquid being measured, especially if dealing with corrosive or aggressive substances.

4. Output Signal Type

Choose Output Signal: Select the appropriate output signal for your system, such as 4-20mA, 0-5VDC, or digital outputs like RS485 or Modbus, to ensure compatibility with your data acquisition or control systems.

5. Environmental Conditions

Operating Environment: Consider the operating environment, including temperature extremes, humidity, and potential exposure to corrosive or hazardous substances. Select a transmitter with appropriate environmental protection ratings (e.g., IP68).

6. Cable Length

Determine Cable Length: Specify the required cable length based on the depth of the tank or well where the transmitter will be installed. Additional length may be needed for routing to the control system.

7. Mounting and Installation Requirements

Mounting Options: Identify the mounting method, whether it requires suspension, flange mounting, or other configurations. Ensure the transmitter is easy to install and maintain in your application.

| Order Guide: |

| BH93420 |

Code |

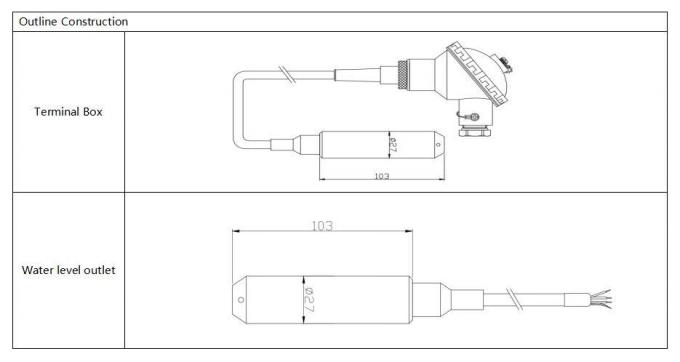

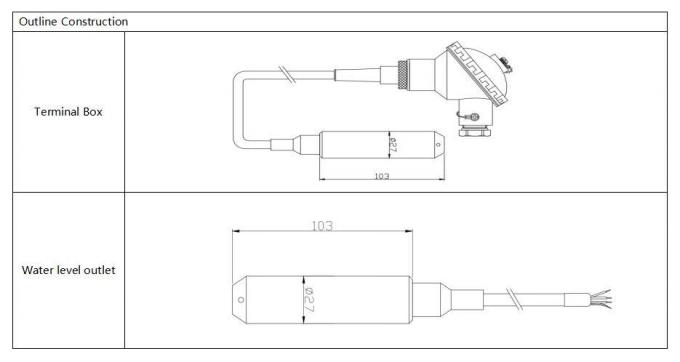

Outline Construction |

| |

I |

Pressure Transmitter |

| |

Measurement Range |

0~10m…400m |

| |

Code |

Power Supply |

| D1 |

24VDC |

| D2 |

5VDC |

| D3 |

Other |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S5 |

0~20mADC |

| S2 |

1~5VDC |

S6 |

0~10VDC |

| S3 |

0~5VDC |

S7 |

0.5~4.5VDC |

| S4 |

0~10mADC |

S8 |

RS485 |

| |

Code |

Pressure Type |

| G |

Gauge Pressure |

| A |

Absolute Pressure |

| S |

Sealed Reference Pressure |

| |

Code |

Material |

| 01 |

304 Stainless Steel |

| 02 |

316L Stainless Steel |

| |

Code |

Cable Material |

| C1 |

PE |

| C2 |

PU |

FAQ:

1. Q: What are the features of your pressure sensor transmitters?

A: High precision, durability, and excellent performance. Customization available.

2. Q: Can I customize special specifications?

A: Yes, our engineers can tailor products to meet specific needs. We provide OEM and ODM service

3. Q: What is your production capacity?

A: Our manufacturing facilities can produce up to 30,000 pressure sensor transmitters per month, so we are fully capable of meeting the needs of large-scale orders. However, it is advisable to contact our sales team in advance to ensure smooth production and delivery scheduling.

4. A: Our warranty time is 24 months after shipment, and our after-sales will respond with your questions in 24hrs, remote instruction by PC network is always available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!