Introduction :

BH93420-I Liquid Level Transmitter that uses HT series diffused silicon isolation oil-filled core as its signal measuring element. It is designed with a full stainless steel housing and a compact one-piece structure. The sensing part of the transmitter that is immersed in the water is completely sealed with stainless steel, ensuring excellent waterproof performance. The product has undergone rigorous high and low-temperature compensation and aging tests, resulting in high reliability and excellent stability.

It Measures the pressure exerted by the liquid column and converts it into a level measurement. The pressure increases with the height of the liquid.

Product Features

1. High Accuracy: ±0.2% FS accuracy for reliable measurements.

2. Wide Measurement Range: Available in ranges from 0 to 10 meters.

3. Robust Construction: Stainless steel housing for excellent durability.

4. Temperature Compensation: Ensures accurate readings across a wide temperature range.

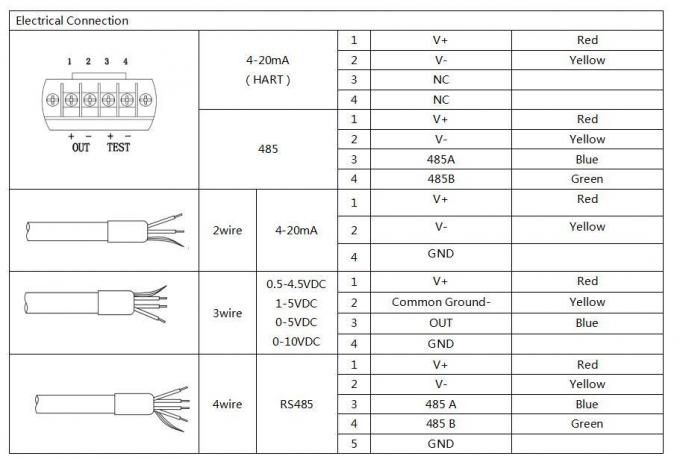

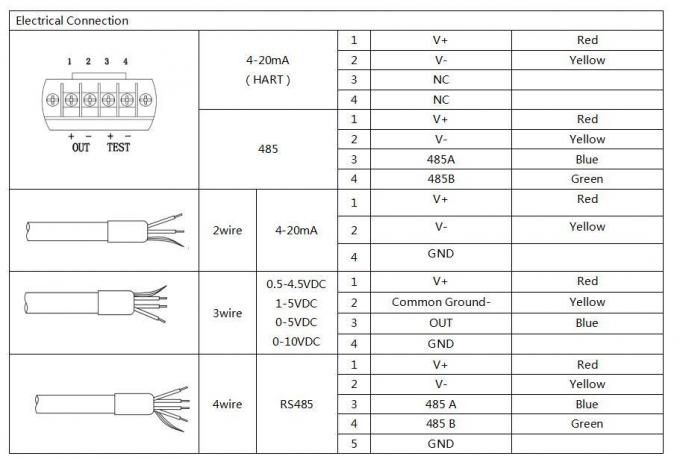

5. Multiple Output Signals: 4-20mA, HART, Modbus options available.

6. Temperature, linearity, hysteresis and repeatability for multi-point calibration

Applications of water level transmitter:

1: Industrial Automation: Monitoring and controlling processes in manufacturing plants...

2. Monitoring water levels in various applications such as sewage, industrial and municipal water, water tanks, wells, rivers, seawater, lakes, etc

3. Measuring fuel levels in diesel and fuel tanks

Performance Parameters:

| Measurement Range |

0~10m…400mH2O |

| Overload |

≤ 2 X of rated range |

| Accuracy @ 25ºC |

±0.25% (Typ.) ±0.5% (Max.) |

| Repeatability |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Hysteresis |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Long-Term Stability |

±0.2%F.S/year (Max.) |

| Zero Point Temperature Drift |

±1.5%F.S(Typ.) ±2%F.S (Max.) |

| Full Scale Temperature Drift |

±1.5%F.Sr(Typ.) ±2%F.S (Max.) |

| Compensation Temperature |

0-50ºC (0-1m. 0-2m ); 0-70ºC |

| Operating Temperature |

-20~80ºC |

| Storage Temperature |

-30~100ºC |

| Vibration |

10g,55Hz ~ 2kHz |

| Housing Material |

1Cr18Ni9Ti |

| Diaphragm Material |

316L Stainless Steel |

| Insulation Resistance |

>=100MΩ@100VDC |

| Explosion-proof Rating |

ExiaIICT6 |

| Protection Rating |

IP67, IP68 |

| O-Ring Seal |

Fluoro rubber |

| Weight |

~0.3Kg (without cable) |

| Cable Material |

Polyethylene, Polyurethane |

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

12~30VDC |

2/3/4 wire |

| 0~10/20mA |

3 wire |

| 0/1~5V |

| 0/1~10V |

| 0.5~4.5V |

5VDC |

| RS485 Communication Protocol |

3.6~30V / Battery |

4 wire |

Ordering tips:

When considering the purchase of diffused silicon pressure transmitters, it's crucial to evaluate several factors to ensure that the selected product meets your specific application needs. Below is a comprehensive guide to help you through the ordering process

1. Please ensure that the measured medium is compatible with the product components in contact with it during selection.

2. The density of the measured medium should be specified.

3. For strong electromagnetic or radio frequency interference, please provide details to our company and indicate it in the order.

4. To ensure the reliable operation of the product, it is recommended that users install lightning protection devices on-site and ensure the product and power supply are reliably grounded.

5.

| Order Guide: |

| BH93420 |

Code |

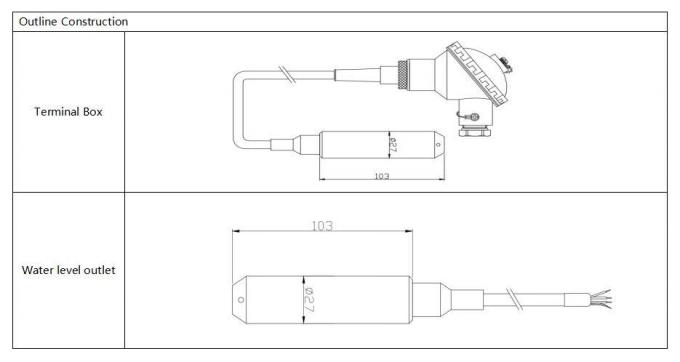

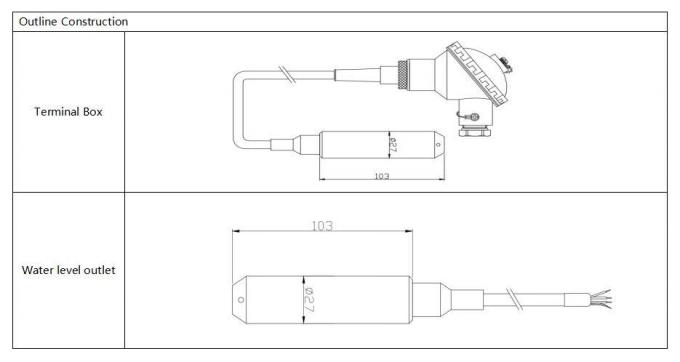

Outline Construction |

| |

I |

Pressure Transmitter |

| |

Measurement Range |

0~10m…400mH2O |

| |

Code |

Power Supply |

| D1 |

24VDC |

| D2 |

5VDC |

| D3 |

Other |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S5 |

0~20mADC |

| S2 |

1~5VDC |

S6 |

0~10VDC |

| S3 |

0~5VDC |

S7 |

0.5~4.5VDC |

| S4 |

0~10mADC |

S8 |

RS485 |

| |

Code |

Pressure Type |

| G |

Gauge Pressure |

| A |

Absolute Pressure |

| S |

Sealed Reference Pressure |

| |

Code |

Material |

| 01 |

304 Stainless Steel |

| 02 |

316L Stainless Steel |

| |

Code |

Cable Material |

| C1 |

PE |

| C2 |

PU |

FAQ:

1. Q: What are the features of your pressure sensor transmitters?

A: High precision, durability, and excellent performance. Customization available.

2. Q: Can I customize special specifications?

A: Yes, our engineers can tailor products to meet specific needs. We provide OEM and ODM service

3. Q: What is your production capacity?

A: Our manufacturing facilities can produce up to 30,000 pressure sensor transmitters per month, so we are fully capable of meeting the needs of large-scale orders. However, it is advisable to contact our sales team in advance to ensure smooth production and delivery scheduling.

4. Q: What's the typical delivery period?

A: 5~7 working day for standard models. Customized products may vary.

5. Q: What is the warranty of your products? And after-sales service?

A: Our warranty time is 24 months after shipment, and our after-sales will respond with your questions in 24hrs, remote instruction by PC network is always available.

6. Q: Do you provide technical support and after-sales service?

A: Yes, we offer comprehensive technical support and after-sales service. Our team is available to assist with product selection, installation guidance, troubleshooting, and any other technical inquiries you may have.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!