BP93420DII Differential Pressure Transmitter

Introduction of differential pressure transmitter:

BP93420DII differential pressure transmitter uses a piezoresistive diffused silicon sensor. The sensor adopts full-automatic linear and temperature compensation technology to ensure the efficiency and quality of mass production. Fully-sealed and isolated air cavity design to

ensure the long term reliability. Signal transmitting module adopts original calibration technology to realize parameters setting easily without any tools.It is suitable for various gas and liquid differential pressure measurements in industries such as petroleum, chemical, power, and hydrology for pipeline applications.

Product Features of differential pressure transmitter:

1. The transmitter features a stainless steel structural design, making it compact and easy to install

2. It undergoes strict temperature compensation and aging screening, ensuring stable and reliable performances

3. Pressure impact tests and time drift tests to ensure constant quality

4. Media work temperature: -30-80℃

5. Intrinsic safety certificate

Applications of differential pressure transmitter:

1. Suitable for measuring differential pressure of various gases or liquids in pipelines of industries such as petroleum, chemical, power, and

hydrology.

2. Applied in industrial on-site processes such as petroleum, chemical, metallurgy, power generation, and hydrology

3.Pressure measurement for pipelines and furnace chambers

| Performance Parameters |

| Measurement Range |

0-10KPa...~2MPa |

| Pressure Type |

Differential Pressure |

| Single-side Overload |

≤3 times of the rated range |

| Static pressure |

The minimum value between 5 times the rated range or 7 MPa |

| Accuracy @ 25ºC |

±0.25% (Typical) ±0.5% (Maximum) |

| Repeatability |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Hysteresis |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Long-Term Stability |

±0.5%F.S/Year(≤200KPa) ±0.2%F.S/Year(>200KPa) |

| Zero Temperature Drift |

±0.01%FS/ºC(>100KPa), ±0.02%FS/ºC (≤100Kpa) |

| Span Temperature Drift |

±0.01%FS/ºC(>100KPa), ±0.02%FS/ºC (≤100Kpa) |

| Compensation Temperature |

0-50ºC(0-10KPa, 0-20KPa) ,0-70ºC ,-10-70ºC |

| Operating Temperature |

-30ºC~80ºC |

| Storage Temperature |

-40ºC~100ºC |

| Vibration |

10g,55Hz ~ 2kHz |

| Housing Material |

304,316L |

| Diaphragm Material |

316L |

| Insulation Resistance |

100MΩ 100VDC |

| Explosion-proof Rating |

Intrinsically safe and explosion-proof |

| Protection Rating |

IP65 |

| Weight |

~0.45kg |

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

12~30VDC |

2/3/4 wire |

| 0~10/20mA |

3 wire |

| 0/1~5V |

| 0.5~4.5V |

5VDC |

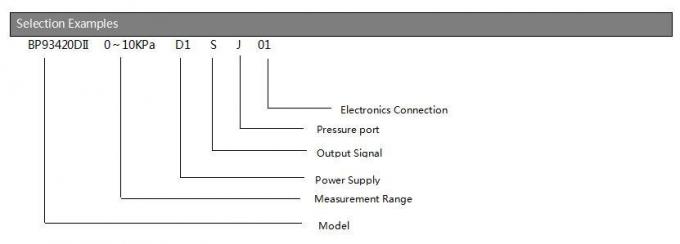

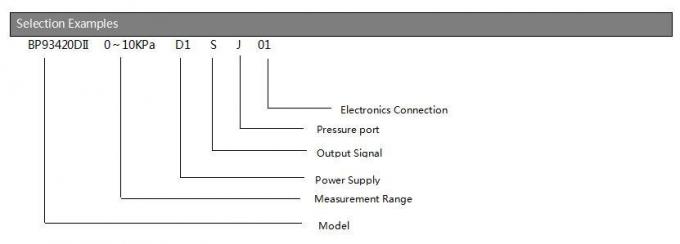

| Order Guide |

| BP93420XX |

Pressure Transmitter |

| |

Code |

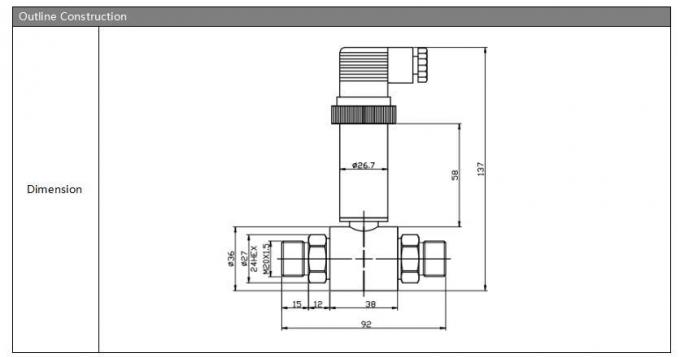

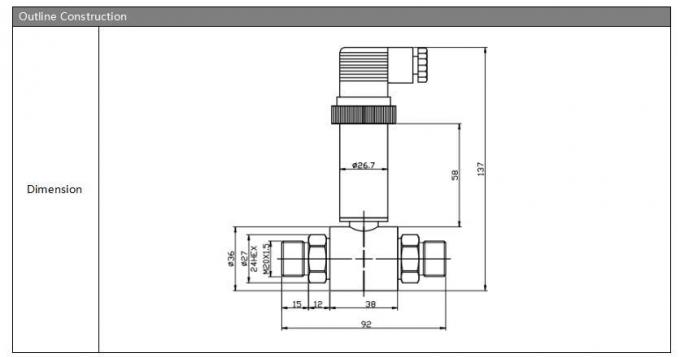

Outline Construction |

| DII |

Differential Pressure Transmitter |

| |

Measurement Range |

0-10KPa...~2MPa |

| |

Code |

Power Supply |

| D1 |

24VDC |

| D2 |

5VDC |

| D3 |

Other |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S5 |

0~20mADC |

| S2 |

1~5VDC |

S6 |

0~10VDC |

| S3 |

0~5VDC |

S7 |

0.5~4.5VDC |

| S4 |

0~10mADC |

|

|

| |

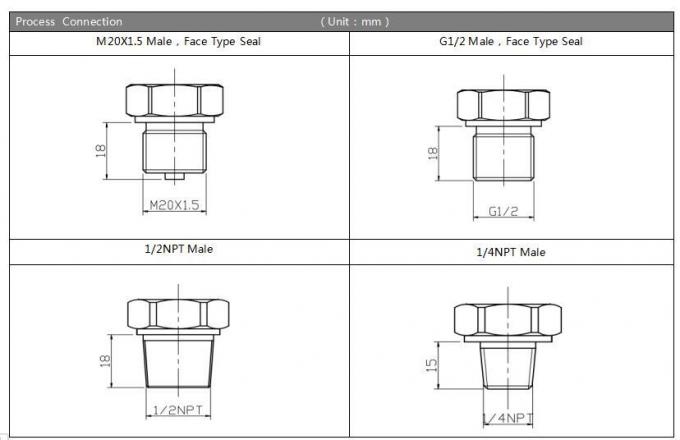

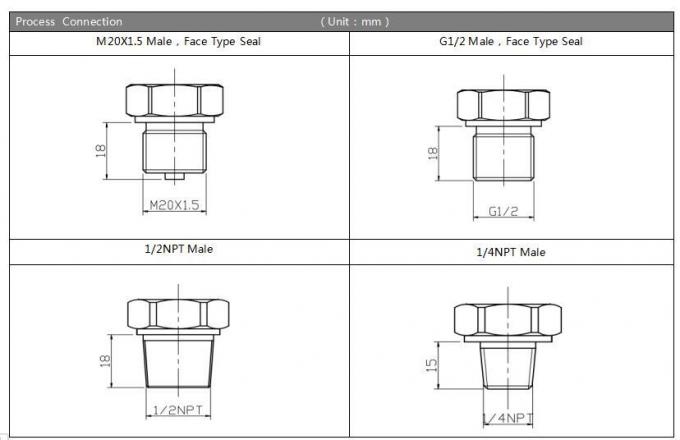

Code |

Pressure Connection |

| J1 |

M20×1.5 Male |

| J2 |

G1/2 Male |

| J3 |

G1/4 Male |

| J4 |

1/2 NPT Male |

| J5 |

Other |

| |

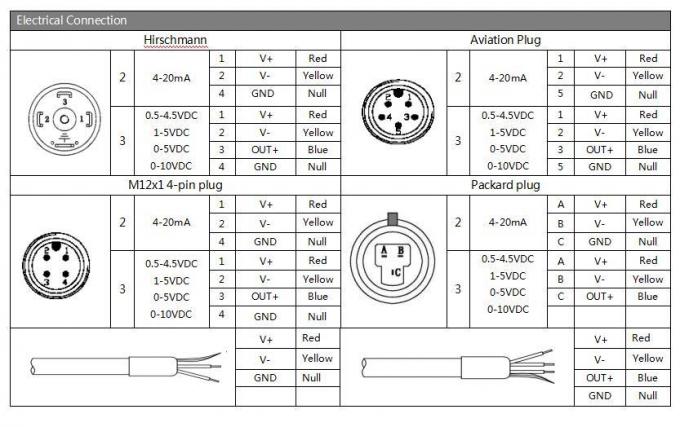

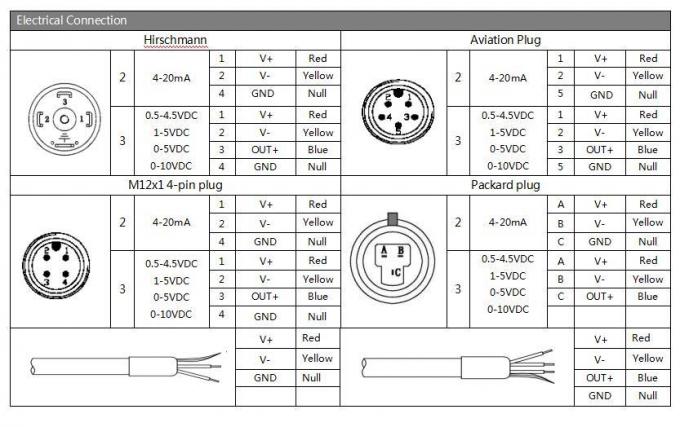

Code |

Electrical Connection |

| B1 |

Hirschmann |

| B2 |

PG7 Plug |

| B3 |

Sealed Cable Output |

| B4 |

Other |

| |

Code |

Pressure Type |

| D |

Differential Pressure |

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!