BPZK01 Digital Pressure Gauge

Introduction:

The BP-ZK01 digital pressure/differential pressure gauge is a versatile measurement and control device that combines precise pressure/differential pressure measurement, clear display, programmable point control, and convenient transmission output. It can be easily installed at the pressure measurement point or integrated into a control panel for testing purposes. It offers user-friendly parameter settings such as zero value, full scale value, and contact pressure value through its intuitive keypad interface

Product Features:

1. Accurate measurement

2. Automatic control

3.Rapid response

4.Multiple output signals

5.Programmability

Applications:

1. Measurement and control of pressure/differential pressure of fluid media in industries such as hydropower, metallurgy, and chemical engineering,

for automatic control applications

| Performance Parameters |

| Measurement Range |

-100kPa…0kPa ~ 10kPa…100MPa |

| 0-10KPa~2MPa(Differential Pressure) |

| Pressure Type |

Gauge Pressure, Absolute Pressure, Sealed Pressure,Differential Pressure |

| Overload |

≤ 1.5 times of the rated range |

| Accuracy @ 25ºC |

±0.25% (Typical) ±0.5% (Maximum) |

| Long-Term Stability |

±0.3%F.S/year |

| Zero Point Temperature Drift |

±0.03%F.S/ºC(≤100KPa) ±0.02%F.S/ºC(>100KPa) |

| Full Scale Temperature Drift |

±0.03%F.S/ºC(≤100KPa) ±0.02%F.S/ºC(>100KPa) |

| Compensation Temperature |

0-50ºC(0-10KPa, 0-20KPa) ,0-70ºC ,-10-70ºC |

| Operating Temperature |

-20ºC~80ºC |

| Storage Temperature |

-40ºC~120ºC |

| Housing Material |

304 |

| Diaphragm Material |

316L |

| Insulation Resistance |

100MΩ 100VDC |

| Relay Control |

1 to 4-channel control |

| Contact Life |

Exceeds 100,000 cycles |

| Display Range |

-1999~9999 |

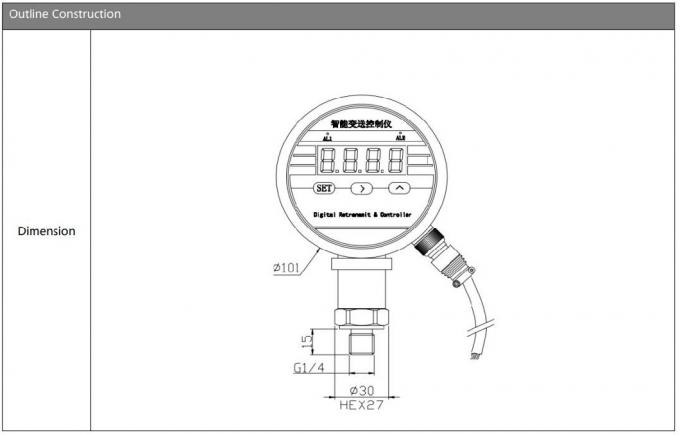

| Installation Method |

vertical axis installation |

| Explosion-proof Rating |

Intrinsically Safe |

| Protection Rating |

IP65 |

| Weight |

~0.5kg |

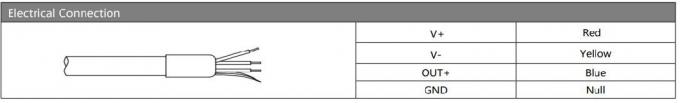

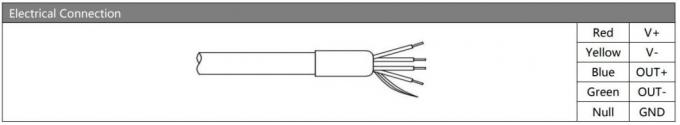

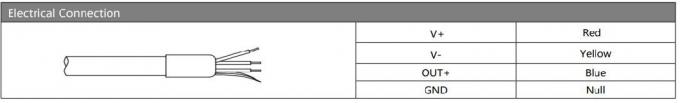

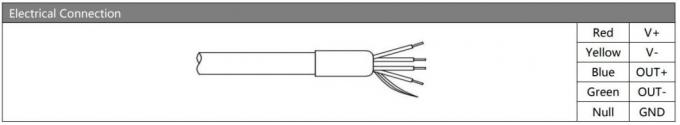

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

24VDC or 220VAC |

3 wire |

Here are some considerations when ordering a pressure controller:

1.Measurement range: Determine the required pressure measurement range to ensure that the measurement range of the selected pressure controller meets the requirements of the application.

2. Accuracy requirements: Understand the accuracy requirements of the pressure controller for the application and select a device with sufficient accuracy.

3. Output signal type: Determine the type of output signal required, such as analog (e.g., 4-20mA) or digital (e.g., RS485), in order to connect to other devices.

4. Power requirements: Understand the power requirements of the pressure controller and ensure that the appropriate power supply can be provided.

5. Installation method: Consider the installation method of the pressure controller, such as mounting directly on the measuring point or mounting on the control panel.

6. Environmental adaptability: Understand the operating environment requirements of the pressure controller, including temperature, humidity, protection level, etc., and ensure that the selected equipment can adapt to these environmental conditions.

7. Programmable function: If parameters need to be set and adjusted according to application requirements, make sure to select a pressure controller with programmable function.

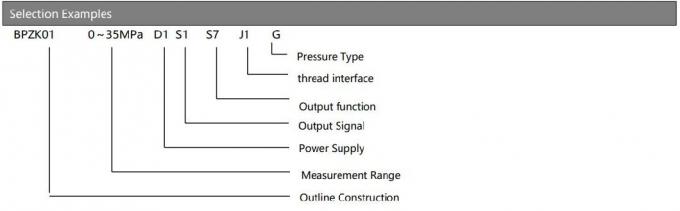

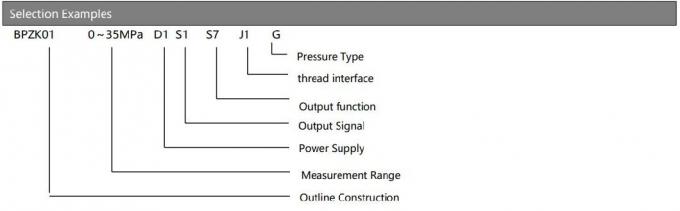

| Order Guide |

| BPZK |

Pressure Transmitter |

| |

Code |

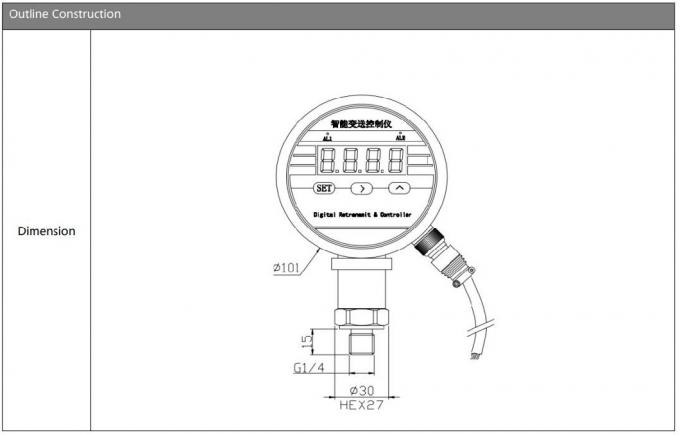

Outline Construction |

| 01 |

Digital Pressure Gauge |

| |

Measurement Range |

-0.1. . .0~0.01...100MPa |

| |

Code |

Power Supply |

| D1 |

24VDC |

| D2 |

220VAC |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S2 |

0~10mADC |

| S3 |

RS485 |

| |

Code |

Output function |

| S5 |

One-channel relay |

| S6 |

Two-channel relay |

| S7 |

Three-channel relay |

| S8 |

Four-channel relayF |

| S9 |

Four-channel relay with RS485 |

| |

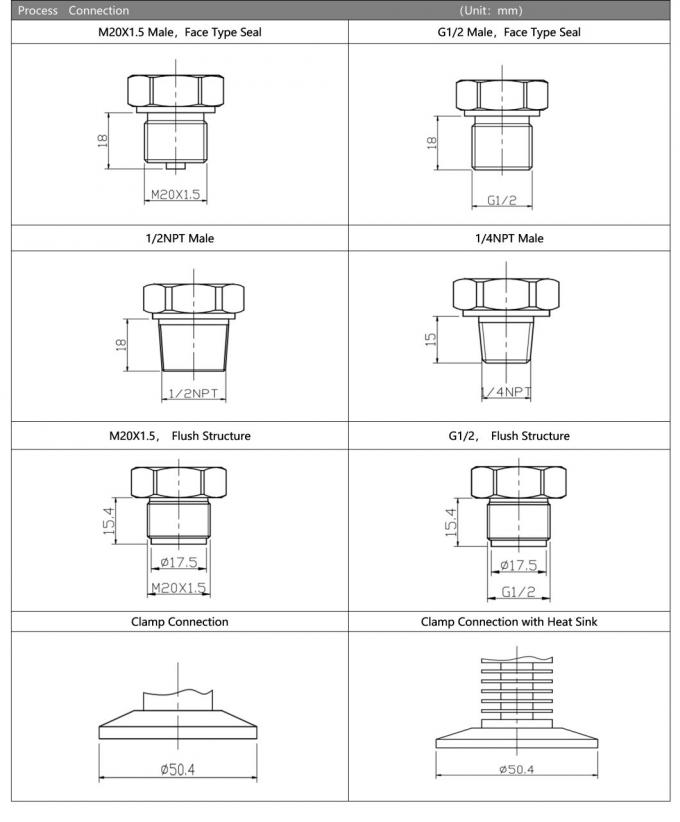

Code |

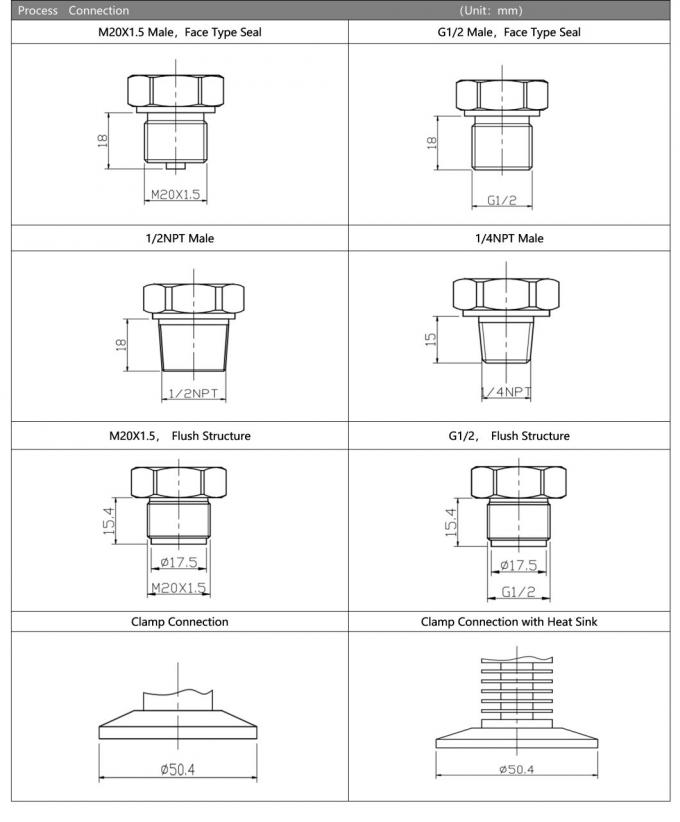

Pressure Connection |

| J1 |

M20×1.5 |

| J2 |

G1/2 Male |

| J3 |

G1/4 Male |

| J4 |

Other |

| |

Code |

Pressure Type |

| G |

Gauge Pressure |

| A |

Absolute Pressure |

| S |

Sealed Reference Pressure |

FAQ:

1. Q: What are the features of your pressure sensor transmitters?

A: High precision, durability, and excellent performance. Customization available.

2. Q: Can I customize special specifications?

A: Yes, our engineers can tailor products to meet specific needs. We provide OEM and ODM service

3. Q: What is your production capacity?

A: Our manufacturing facilities can produce up to 30,000 pressure sensor transmitters per month, so we are fully capable of meeting the needs of large-scale orders. However, it is advisable to contact our sales team in advance to ensure smooth production and delivery scheduling.

4. Q: What's the typical delivery period?

A: 5~8 working day for standard models. Customized products may vary.

5. Q: How are the products priced? Any discounts?

A: Competitive pricing with discounts for bulk orders or long-term partners.

6. Q: What is the warranty of your products? And after-sales service?

A: Our warranty time is 24 months after shipment, and our after-sales will respond with your questions in 24hrs, remote instruction by PC network is always available.

FAQ:

1. Q: What are the features of your pressure sensor transmitters?

A: High precision, durability, and excellent performance. Customization available.

2. Q: Can I customize special specifications?

A: Yes, our engineers can tailor products to meet specific needs. We provide OEM and ODM service

3. Q: What is your production capacity?

A: Our manufacturing facilities can produce up to 30,000 pressure sensor transmitters per month, so we are fully capable of meeting the needs of large-scale orders. However, it is advisable to contact our sales team in advance to ensure smooth production and delivery scheduling.

4. Q: What's the typical delivery period?

A: 5~8 working day for standard models. Customized products may vary.

5. Q: How are the products priced? Any discounts?

A: Competitive pricing with discounts for bulk orders or long-term partners.

6. Q: What is the warranty of your products? And after-sales service?

A: Our warranty time is 24 months after shipment, and our after-sales will respond with your questions in 24hrs, remote instruction by PC network is always available.

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!