BH93420 II Water level Transmitter

Introduction of water level tramsmitter:

The BH93420-II water level transmitter is an advanced level measuring equipment, which uses high-precision diffused silicon sensor to accurately measure the height or pressure of liquid utilizes a high-precision diffused silicon piezoresistive pressure sensor as the signal measuring element. The millivolt signal obtained from the static pressure measurement, which is directly proportional to the liquid height, is converted into a standard signal output through amplification circuitry. By establishing a linear correlation between the output signal and the liquid height, it enables accurate measurement of the liquid level.

Product Features of water level transmitter:

1.Split-type design, facilitating on-site wiring and calibration

2.LED or LCD display

3.Explosion-proof rating ExiaIICT6

4.High protection : IP68

5.PE , PU. PTFT

Applications of water level transmitter:

1.Compatible with 316LSS,noncorrosive liquids

2.Monitoring water levels in various applications such as sewage, industrial and municipal water, water tanks, wells, rivers, seawater, lakes, etc

3.Measuring fuel levels in diesel and fuel tanks

4. It is widely used in chemical, petroleum, power, water treatment and other fields, providing a reliable liquid level measurement solution for industrial production

| Performance Parameters |

| Measurement Range |

0~10m…400mH2O |

| Pressure Type |

Gauge Pressure, Absolute Pressure, Sealed Pressure |

| Overload |

≤ 2 X of the rated range |

| Accuracy @ 25ºC |

±0.5% (Typ.) ±0.1% (Max.) |

| Repeatability |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Hysteresis |

±0.03% (Typ.) ±0.05%FS (Max.) |

| Long-Term Stability |

±0.15%F.S/year (Max.) |

| Zero Point Temperature Drift |

±1.5%F.S(Typ.) ±2%F.S (Max.) |

| Full Scale Temperature Drift |

±1.5%F.S(Typ.) ±2%F.S (Max.) |

| Compensation Temperature |

0-50ºC (0-1m ,0-2m); 0-70ºC |

| Operating Temperature |

-20~80ºC |

| Storage Temperature |

-30~100ºC |

| Vibration |

10g,55Hz ~ 2kHz |

| Housing Material |

Cast aluminum, 1Cr18Ni9Ti |

| Diaphragm Material |

316L Stainless Steel |

| Insulation Resistance |

>=100MΩ@100VDC |

| Explosion-proof Rating |

Intrinsically Safe |

| Protection Rating |

IP68 |

| O-Ring Seal |

Fluoro rubber |

| Weight |

~1.1Kg (without cable) |

| Cable Material |

Polyethylene, Polyurethane, PTFE cable |

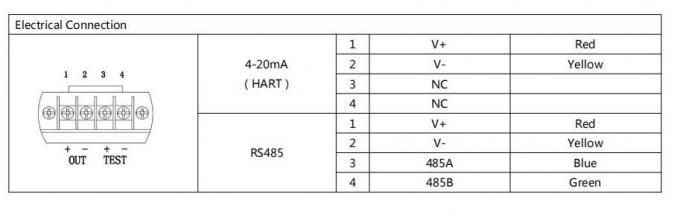

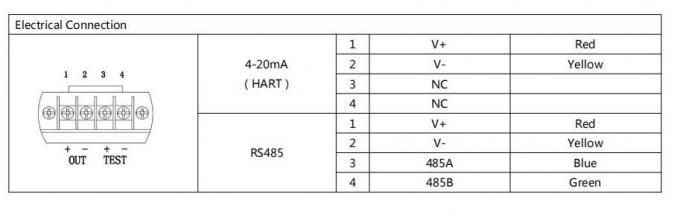

| Output Signal |

Supply Voltage |

Output Type |

| 4~20mA |

15~30VDC |

2/3/4 wire |

| RS485 Communication Protocol |

4 wire |

1. please ensure that the measured medium is compatible with the contacting parts of the product.

2. The density of the measured medium should be specified.

3. For special requirements such as strong vibration, instantaneous impact force, strong electromagnetic interference, or radio frequency interference, please inform our company and specify in the order.

4. To ensure the reliable operation of the product, it is recommended that users install lightning protection devices on-site and ensure the product and power supply are reliably grounded.

5. When equipped with an LED or LCD display head, the transmitter power supply voltage should not be lower than 15VDC.

6. The installation position should be reasonable, avoid external interference and damage, and facilitate maintenance and cleaning.

7. The equipment should be checked and calibrated before installation to ensure that it is working properly.

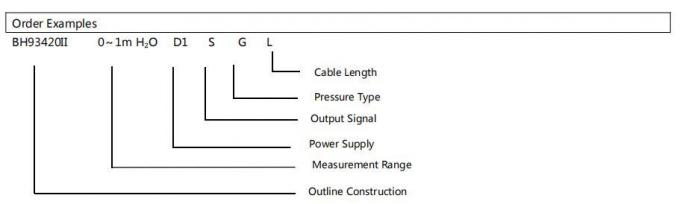

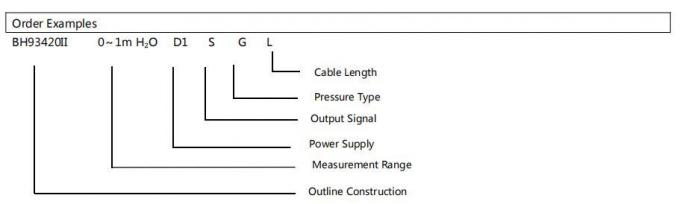

Order Guide:

| BH93420 |

Code |

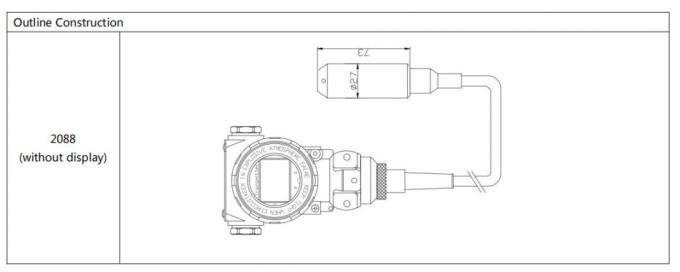

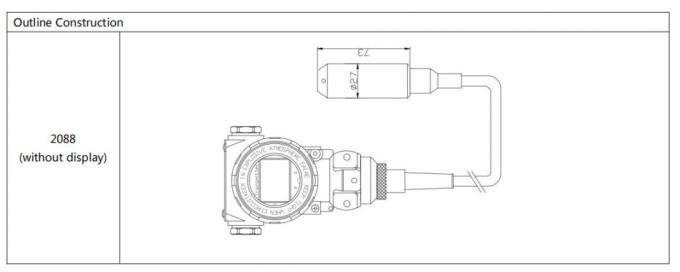

Outline Construction |

| |

II/III |

Liquid level transmitter with the 2088 housing |

| |

Measurement Range |

0~10m…400m |

| |

Code |

Power Supply |

| D1 |

24VDC |

| |

Code |

Output Signal |

| S1 |

4~20mADC |

S2 |

RS485 |

| |

Code |

Electrical Connection |

| B4 |

2088 industrial housing |

| B5 |

2088 with display |

| |

Code |

Pressure Type |

| G |

Gauge Pressure |

| A |

Absolute Pressure |

| S |

Sealed Reference Pressure |

| |

Code |

Material |

| 01 |

304 Stainless Steel |

| 02 |

316L Stainless Steel |

| |

Code |

Cable Material |

| C1 |

PE |

| C2 |

PU |

| C3 |

PTFT |

| |

|

Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!  Your message must be between 20-3,000 characters!

Your message must be between 20-3,000 characters! Please check your E-mail!

Please check your E-mail!